Subject

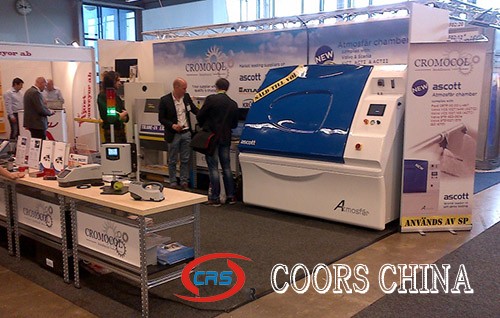

Launch of new Atmosfär chamber at Scandinavian Coatings Show

Key Benefits

Specially designed chamber for Volvo & Ford CCT test standards

Key equipment facts

|

Ascott are pleased to announce that their ‘new baby’ was safely delivered at the Scandinavian Coatings Show in May after a successful 18 month gestation! The Volvo & Ford CCT test standards are unlike other automotive corrosion tests in the way the salt solution is applied to the samples. The application method is to spray this solution directly on to the samples under test from a swaying spray-bar, located high above the samples. During this phase of the test cycle, the spray bar sways backwards and forwards inside the chamber, spraying salt solution from an array of specially selected spray nozzles, each with a ‘fan shape’ spray pattern. This creates a uniform spray which is then ‘swept’ over the surfaces of the samples under test, as the spray bar sways backwards and forwards. However, thanks to its unique design - featuring a novel magnetic drive system for the spray bar, this can also easily be removed to allow the chamber to comply with other more conventional salt spray and CCT specifications, using the usual Ascott salt spray atomiser which is also fitted as standard. In addition, the Atmosfär is supplied with a separate refrigerated air conditioning unit which circulates temperature and humidity controlled air through the chamber. This is required at certain points in the above tests in order to achieve low controlled humidity levels as well as rapid rates of change to the temperature and humidity. This unit also has the ability to refrigerate the chamber to –20C, if and when required by other tests standards, or if the user is interested in examining the performance of their products under freeze/thaw conditions. |